WAREHOUSE - SMART - SEMI-AUTOMATIC

SMT (Surface Mount Technology) FACTORY DIGITAL TRANSFORMATION

- Nowadays. Surface Mount Technology (SMT), with a system of high-precision and high-performance machinery, opens up outstanding Production capacity, ensuring good Technical requirements and Product quality.

- In the Production processes, in addition to the Machine factor, there is still a need for Human resources including Technicians, Equipment Operators and an attached Production processes, including Forms, Check sheets and Handwritten Reports…

- The Quality problems come from the Manuals of operations such as Wrong connection of component coils, Wrong check sheets, Wrong Forms, Bypass operation, Just do it and Report later (Then forget to Report, forget to Take notes)

- Visual checks …. More emotional than working, making processes Uncontrollable – Measurable and resulting in the error being untraceable.

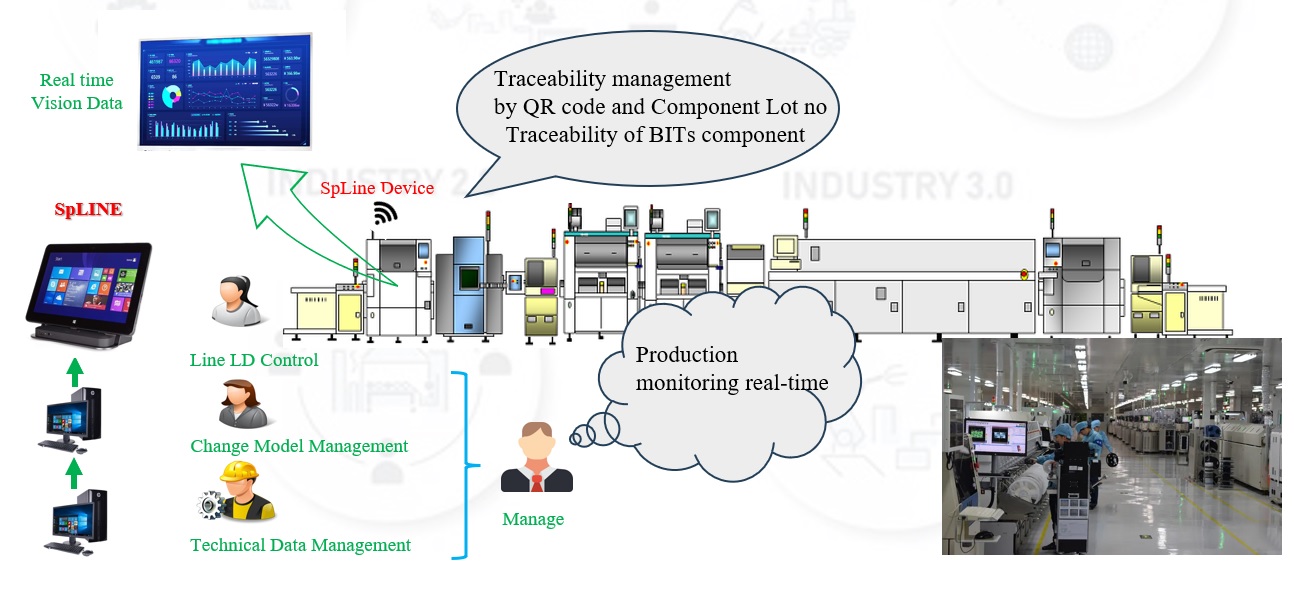

The SpLINE digitization solution suite is ISO – 9001 integrated production management software that helps managers CONTROL-OPERATE their work more effectively and practically.

SpLine software is a Module in the MES ecosystem of HVDNA.Co.,Ltd.

Helping Enterprises take steps from partial digitization to full digitization without affecting existing BUSINESS OPERATIONS. Helping Enterprises solve the OPTIMIZATION – HIGH EFFICIENCY problem.

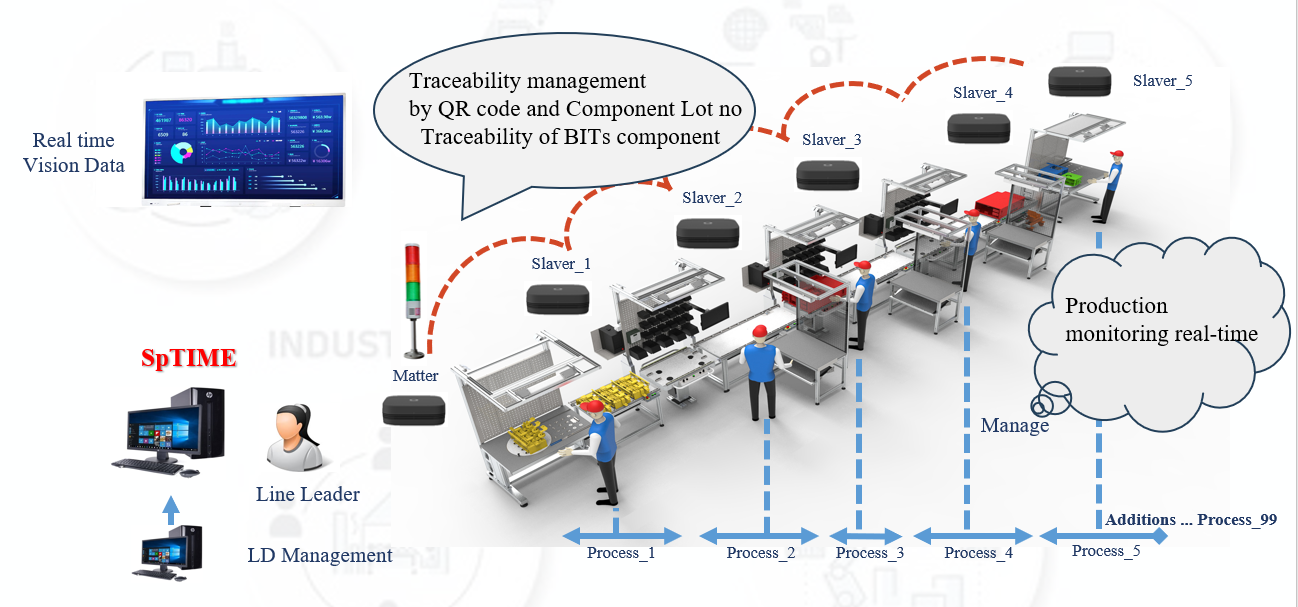

DIGITAL TRANSFORMATION - ELECTRONIC ASSEMBLY FACTORY (ASSY)

PRODUCTION & ASSEMBLY Is the final stage of the production, Finishing good products, Delivering to customers.

With the specificity of the Production – Assembling Department, 80% of the factory’s direct workers are involved in concentrated production in this Department, with many different levels of unskilled labor.

The Challenge for Production managers is how to ensure the Complete Production plan and Shipment plan.

Some of the factors that must be mentioned are how to ensure Productivity and improve Productivity, Next is the Operation and Management of the production line to ensure the Quality of output products.

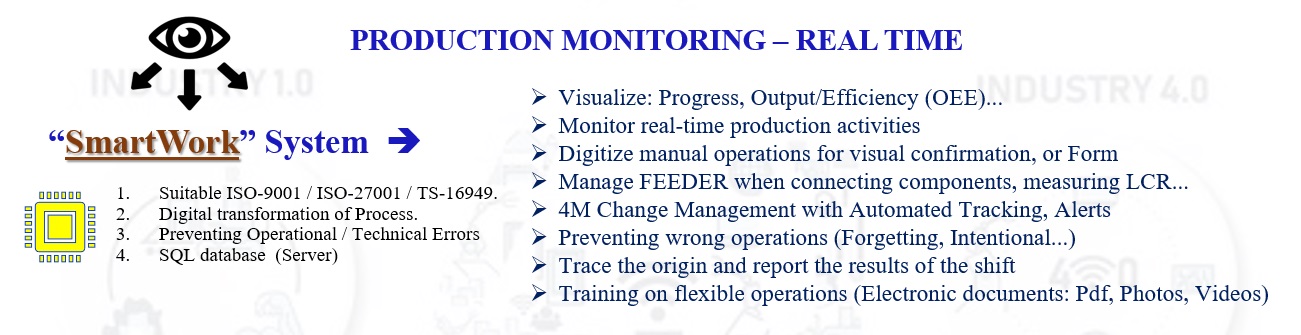

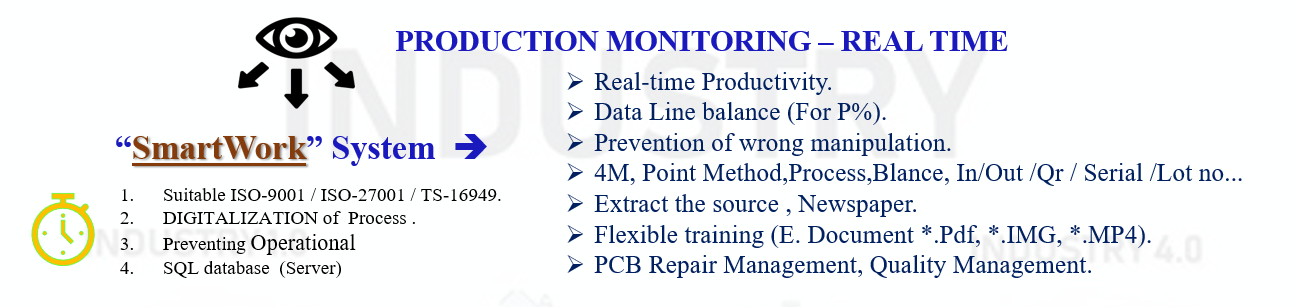

The solution that HVDNA offers is SMARKWORK production management software

Integrating ISO – 9001 processes into Production processes Flow Management

SMARKWORK software is a Module in HVDNA’s digitization ecosystem.

Helping Enterprises take steps from partial digitization to full digitization without affecting current BUSINESS ACTIVITIES. Help Enterprises solve the OPTIMIZATION problem – HIGH EFFICIENCY.

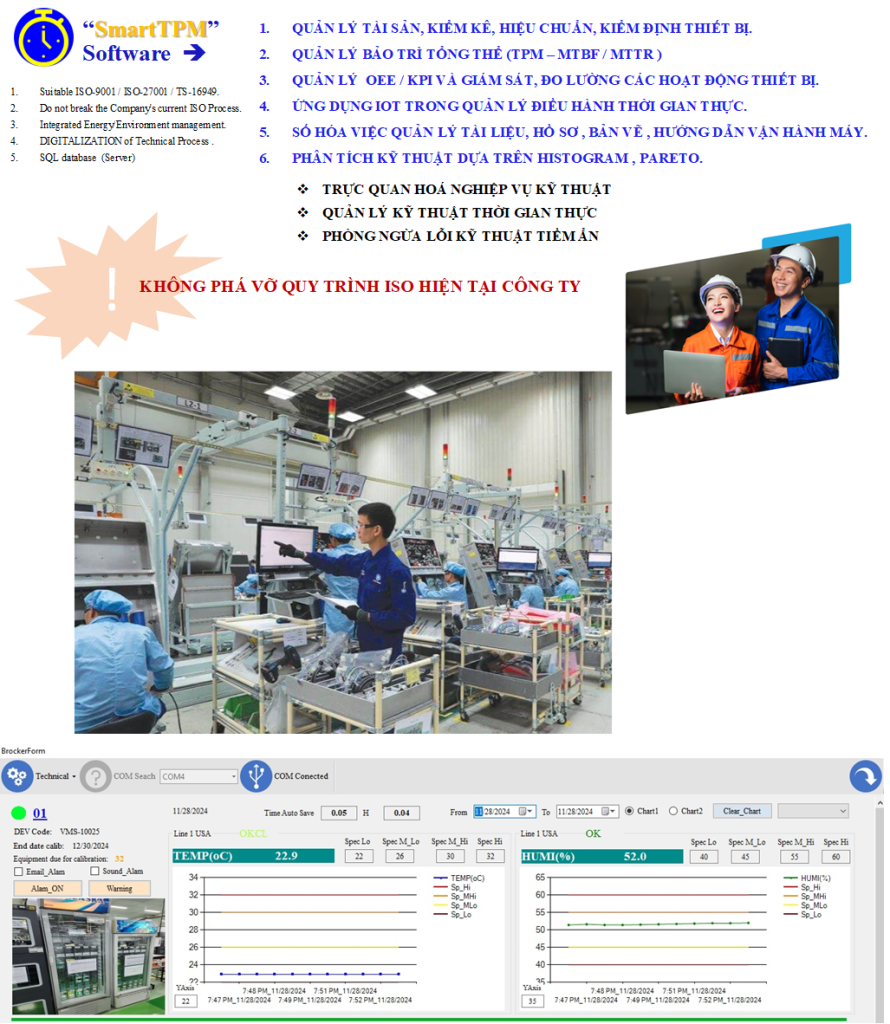

DIGITIZATION for PRODUCTION ENGINEERING

PRODUCTION ENGINEERING is an integral part of the Production block, with functions and tasks such as.

- Management of machinery, Equipment and factories

- Maintenance, Maintenance

- Operation and repair of electrical systems

- Operate machinery on the production line

- Checking, Repairing, Debugging Machines on Production Line

- Setup, Install the software on the Function circuit tester (ICT/FCT….)

- Control the Standard parameters of Machine operation ….Drawing ….

A skilled Technical team with a process of many Check sheets, The Operation by Sample check,Measurement, …..

With the DIGITAL PRODUCTION ENGINEERING solution, Create a SYSTEM link to connect information with each other to help technicians simpler and more accurate in CHECKING – CONFIRMING the normal operations of the machine.

ENGINEERING TEAM

” SMART TMP SOFTWARE “

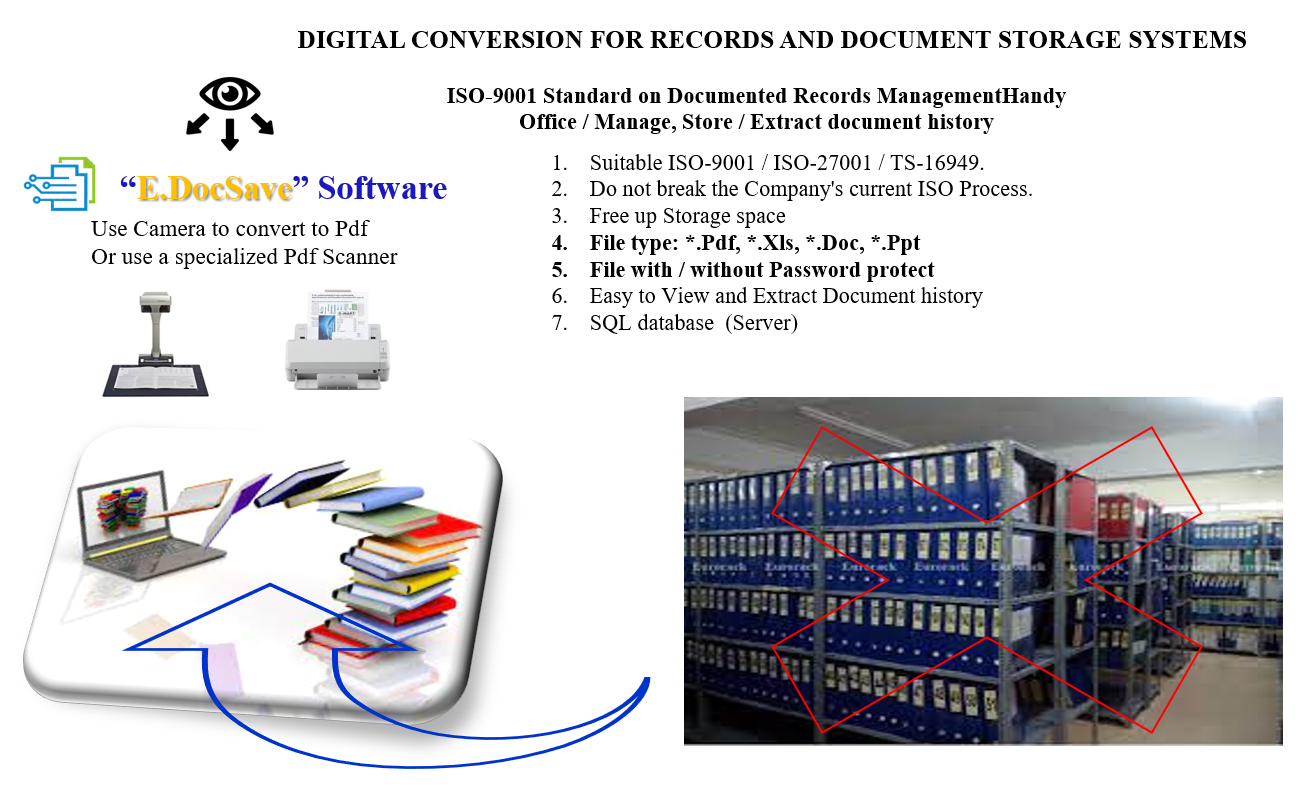

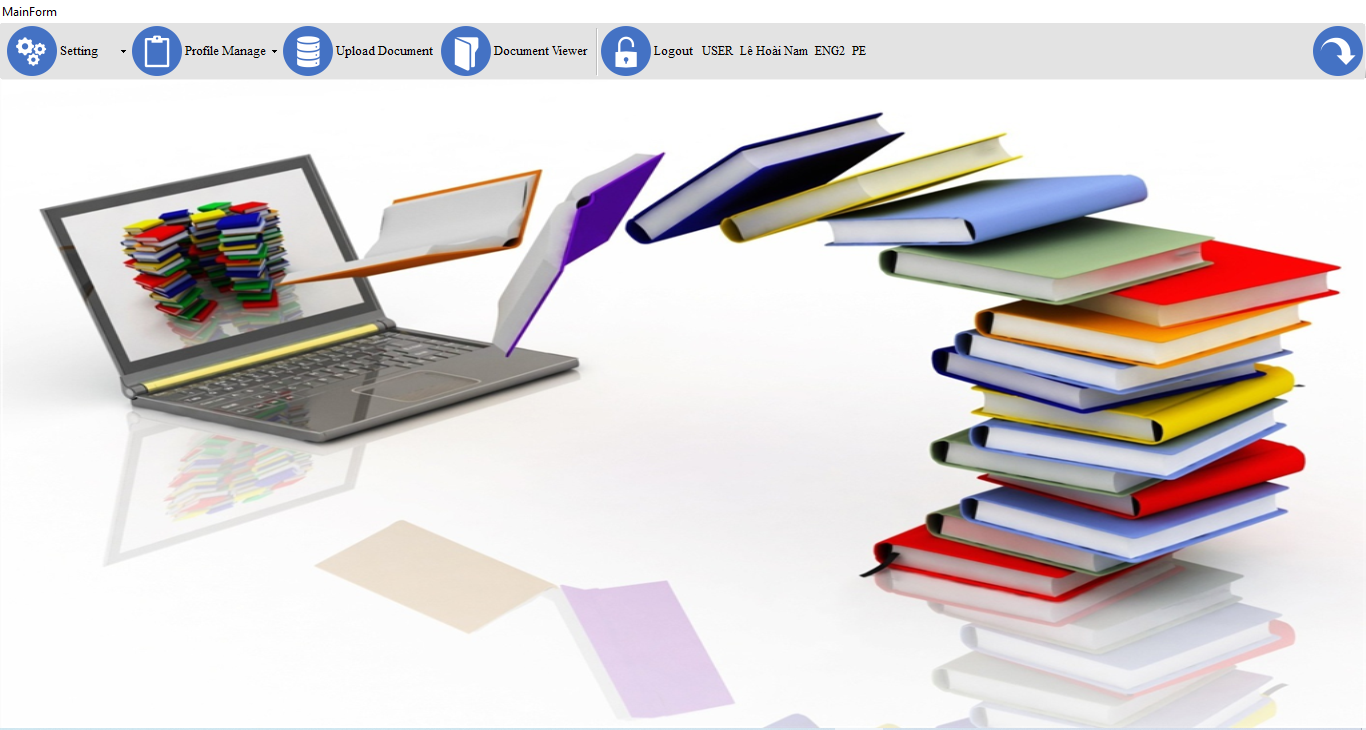

DOCUMENT DIGITIZATION SOLUTION (Integrating ISO-9001 & ISO-27001 (ISMS)

Talking about DIGITIZATION SOLUTIONS, it is impossible not to mention the management of RECORDS – STORAGE.

Form files, Paper production report files… usually take up a lot of Storage space, and there are many potential causes leading to Fire and Explosion….

In fact, there are many methods of DIGITALIZING all kinds of RECORDS.

HVDNA’s digitization solution suite complies with ISO-9001 standards for Documentary Records Management to help businesses not break the processes. Ensure convenience for daily storage of working departments.

“E.DocSave” Software

DIGITAL OFFICE SOLUTIONS

IoT SOLUTIONS for SMART FACTORY

IoT is a Terminology familiar to Everyone.

However, its application in Manufacturing practice is an issue that needs to be properly considered, in order to participate effectively in the PRODUCT CREATION processes….

To solve the problem of PRACTICAL APPLICATION IN PRODUCTION. HVDNA has built a Smart_IoT system based on an open source Platform that allows embedding HVDNA’s devices into production practice through commercially available sensors of famous brands such as SMC, OMRON, KEYENC …helps reduce production costs, Bring high practical efficiency.

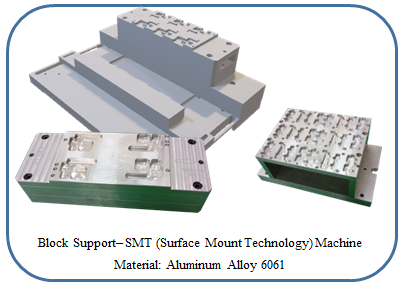

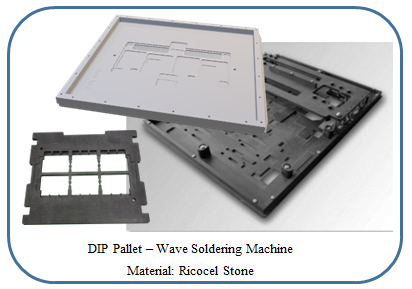

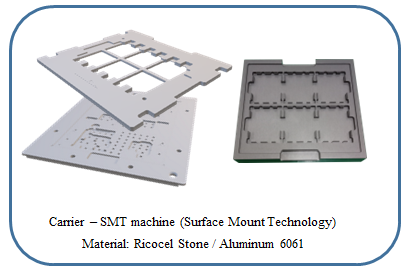

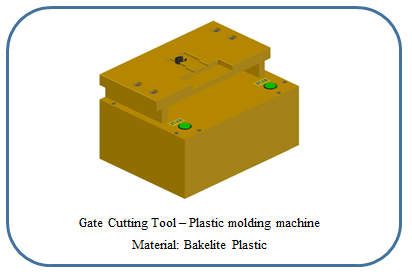

DESIGN - MANUFACTURING TOOLS , ANTI-Mistakes Tools

- Jig, Fixture and Auxiliary Tools are Technical Terms used to refer to Tools, Support for the manipulator to complete the product.

- As a Tool to help Operators Lift, Support, Shield, Shape, Quantify, Orient, Fix and Confirm…. Assembly.

- Understanding the importance of the Tools, you will see it as very important in the processes of creating VALUE for Products.

- Aware of that problem, HVDNA proposes Solutions for making Quality Assurance Tools and Product Operation Safety.

- Depending on the Operation, Product Function in the processes, each Tool has its own characteristics to ensure accuracy based on HVDNA’s Knowledge and Experience.

Procedure.

- Collect customer requirements (Drawings, Real objects…Other requirements)

- Design Analysis – 3D

- Exchange of information – Quotations – Contracts

- Executing the job on the CNC machine

- QC Check out the shipment.

- Transfer.

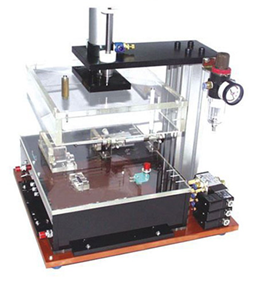

DESIGN ICT/FCT Machine

- Design in the form of Blocks (Modules)

- Easy to connect or disassemble (Fixture – Cable – Control box – Computer – Instrumentation)

- Easily change the model for the model series (Replace Fixture + Setting file)

- Equipment is used with products from big brands such as National Instruments NI-488.2, Hioki, ICP DAS, Dell

SOFTWARE FEATURES

- Create a new program of Test steps set by the user setting

- Built-in automatic Barcode Reader function, Marking products OK checked.

- OK/NG Product management through Interlock .

- Allows saving data by Log File, and extracting test results and reports.

- Intelligent data filtering mode helps technicians analyze product quality via a Histogram chart.

- Operation 2 modes Auto and Manual help Debug.

- The feature of displaying NG error messages at the step of error (Help recording red Notes)

TEST FUNCTION

- According to specific Product function

Procedure

- Receive customer requirements (Drawing, Gerber File, Other requirements…)

- Analysis – Design – Selection of Equipment.

- Send the design to the Customer for approval.

- Quotation – Contract.

- Manufacturing machines according to the signed contract term.

- Handover – Debug – Warranty

- Support after-sales services (Consultancy – Repair – Replacement – Improvement upgrade …)

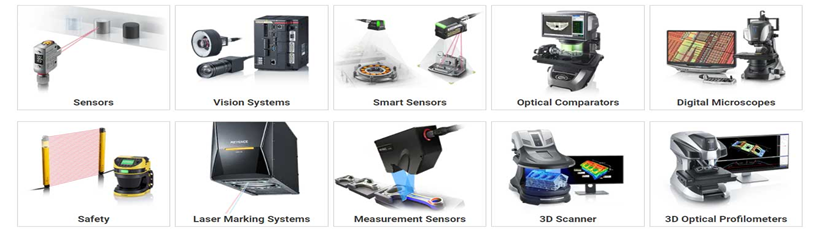

SUPPLY OF INDUSTRIAL MACHINERY MATERIALS, EQUIPMENT

Supply all Spare part & Machine with Technical Service support

Equipment and Sensors

Materials for making Tools

Tiếng Việt

Tiếng Việt 日本語

日本語